MEMS TECHNOLOGY

HT MICRO

TECHNOLOGY

THE HT DIFFERENCE

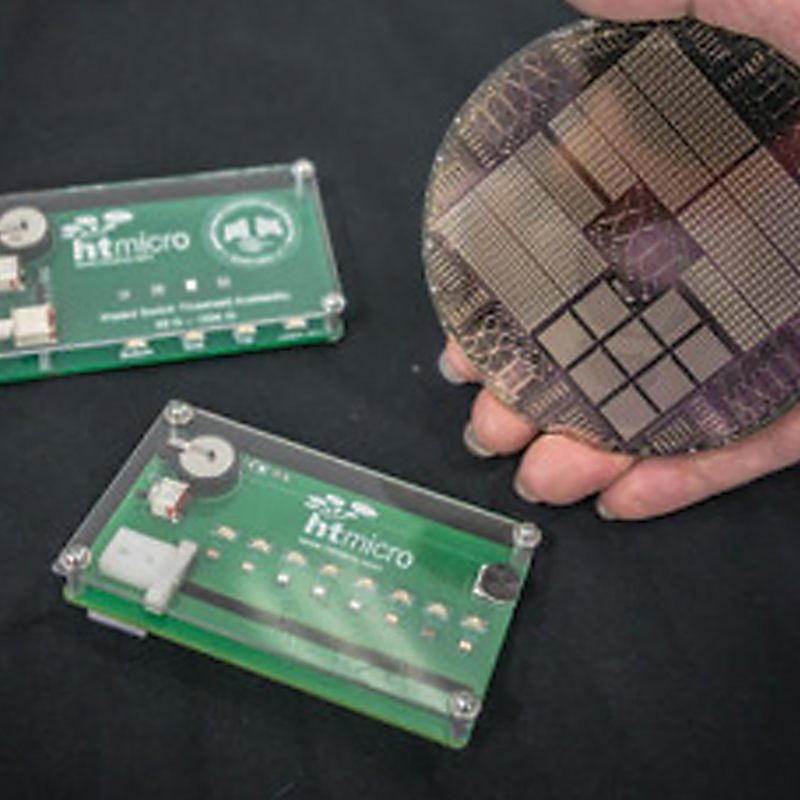

HT Micro is leading the way to replace conventionally manufactured switches, connectors, and machined parts with the smallest, most reliable metal microfabricated products in the world. The Company’s array of integrated micro-devices employs proprietary Microelectromechanical Systems (MEMS) LIGA processes (lithographic electroforming), metal materials, high aspect ratio manufacturing, and wafer level parallel processing to achieve rugged, high performance, miniaturized solutions for the medical, military, industrial, and consumer electronics applications.

Precision

The ability to maintain tolerances at small dimensions is at the core of HT’s products and processes. HT’s expertise is in developing fabrication processes that maintain critical dimensions using a low-cost manufacturing process. Traditional machining techniques are being replaced with HT’s core microfabrication techniques – electroforming, UV lithography, thick metal plating, batch processing, and wafer-level packaging and testing.

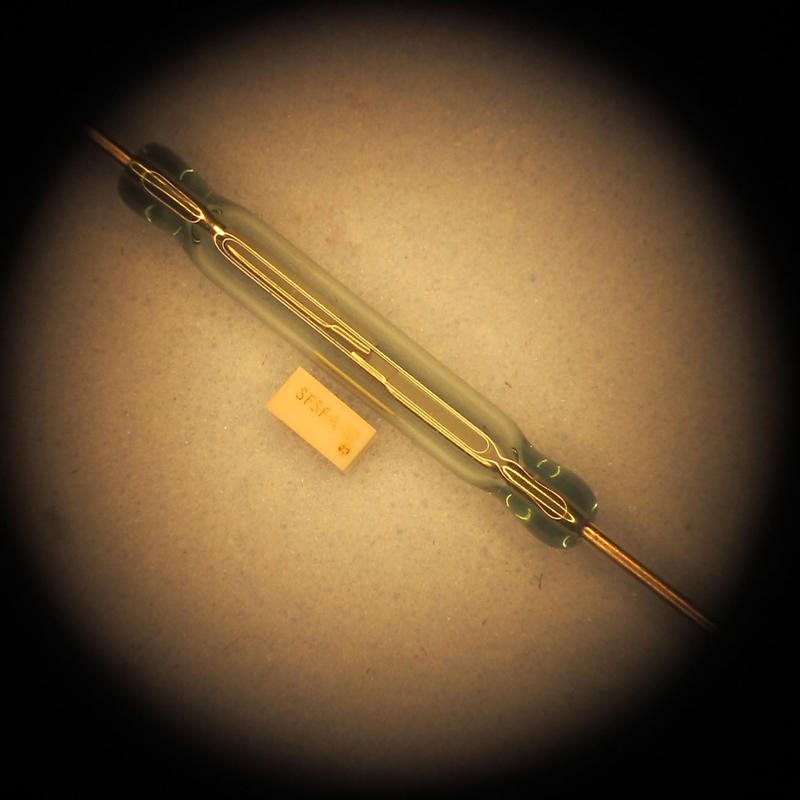

High Aspect Ratio Manufacturing

HT Micro designs, develops, and manufactures metal MEMS sensors, switches, and components. Combining state of the art high aspect ratio lithography and electroforming with MEMS designs HT enables production of complex three-dimensional mechanisms that maintaining tolerances in the sub-millimeter range. The technology’s advantage comes from the ability to perform wafer level processing within a very broad range of materials. The technology for wafer level processing is well known in the IC industry; however, precision mechanical fabrication in a wide variety of metals is not. HT Micro has advanced processes that enable miniaturization of magnetic and mechanical switch components without sacrificing performance. HARM allows for designs with an out of the plane feature height considerably greater than the width of the feature. This aspect ratio creates more area for flexures employed in mechanical designs. Reliability is the benefit of the high aspect ratio fabrication.

Integrated Metal Fabrication

A continual focus on the aggressive expansion of the available processing materials base and integration capabilities is driving reliability, low cost manufacturing, and reduced product sizes. Our additive metals based technology and integrated packaging approach is especially suited to markets requiring rugged and resilient components.

Wafer Level Packaging

HT’s processes enable product designs with the unique value-added benefit of directly packaging on the wafer. The self-packaging methodology lends itself directly to hermetically sealed components which are rugged enough for military and industrial applications. The components have the ability to withstand extreme temperature variations, vibration, and g-forces. Batch microfabrication supports wafer level packaging, avoiding expensive and time-consuming back-end of line assembly and testing.